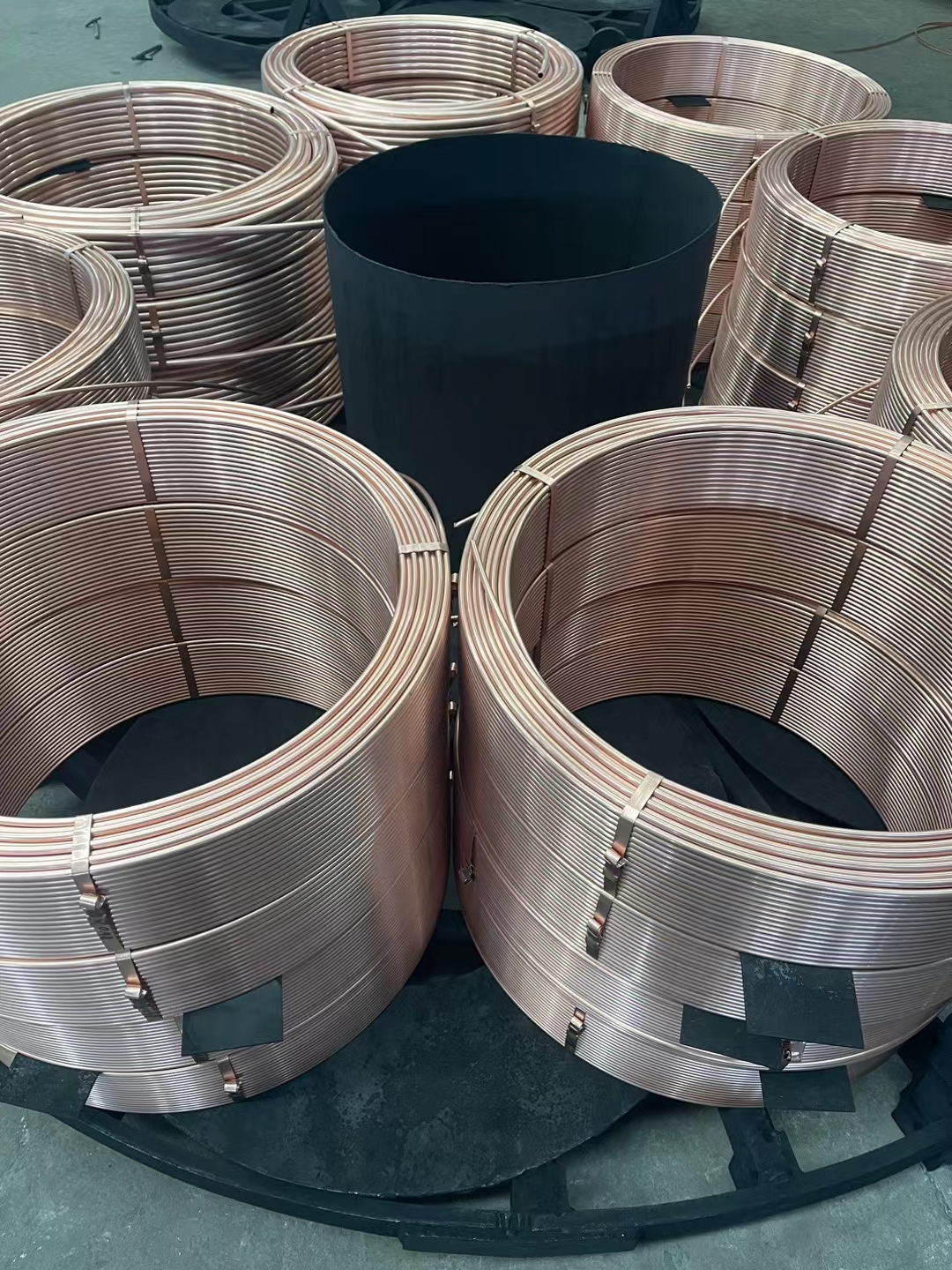

Product name:Pancake copper Tube

Item: copper tube / copper tubes / copper tubing / copper piping / copper coil / pipe coil

Details:

Pancake copper tube coils for HVAC&R industry

Pancake copper tube coils mainly be used for Air Conditioning and Refrigeration,water systerm,LP gas and medicial gas susterm Field Service, such as Heat Exchange use, Connecting tube, Distribution, Natural Gas with easy transport and installation characteristic

Main material: 99.99% copper

General size:

1)Grade : C1100,C1020, C1220, CU-DHP

2)Outside Diameter: 3/16″ 1/4″ 5/16″ 3/8″ 1/2″ 5/8″ 3/4″ 7/8″

3) Wall Thickness: 0.014”-0.059”

4)Length: 30′ 50′ 100′ etc ,Generally for the single layer packing is 15m(max),for the double layer packing is 30m-50M(max)

Production Standard:

1)ASTM B280, AS/NZS 1571 JISH3300 and EN 12735 for air conditioner and refrigerator systerm

2)ASTM B88 EN1057 AS1432 for plumbing water systerm

3)ASTM B837 for LP gas systerm

4)EN 1348 for medical gas systerm

Copper tube Temper:Soft

Package:Each end capped ,put into general bags or shrink bags and then put into the cartons

Product code and size:

| Standard size

inch |

Temper | Outside diameter

mm |

Wall thickness

mm |

Length m |

| 3/16 | Soft or Half hard | 4.75 | 0.76 | 3-30 |

| 1/4 | 6.35 | 0.76 | ||

| 5/16 | 7.94 | 0.81 | ||

| 3/8 | 9.52 | 0.81 | ||

| 1/2 | 12.7 | 0.81 | ||

| 5/8 | 15.88 | 0.889 | ||

| 3/4 | 19.05 | 0.889 | ||

| 3/4 | 19.05 | 1.07 | ||

| 7/8 | 22.23 | 1.14 |

Atten: the O.D and WT no need according to the international stardands strictly, shoud be lead as youe market

Copper Pipes Description:

Application: Air Conditioner, Refrigeration & Heat Exchage field etc.

Alloy No.: C12200, C1220 & TP2 etc

Temper: Soft Drawn, Light Soft Drawn, Hard & Half Hard.

Standard:ASTM B280, EN 12735, JISH 3300, GB/T 1527 & AS/NZS 1571 etc

Package: Ends capped, Bundled into Plastic Bag, Packed in the wooden box as well container.

Remarks: The Outside Diameter with revent wall thickness Available.

1. QC & Technical Support:

We have advanced testing equipment for fault analysis and product full-function inspections.

Our experienced engineers and precision equipment mean products that meet your exacting requirements.

2. Materials & Components:

Most of our materials is supplied from reliable suppliers.

Procedures & Test Details:

We thoroughly inspect each raw material.

Our production is supervised by engineers who are extremely cautious about product quality & details.

3. Raw Material Supplying:

Raw material sourcing from select suppliers

Product testing using different detecting instruments

Periodical testing during the production process

Final quality inspection before shipment

Copper Tubes Chemical & Mechanical Property:

| Copper Alloy No. | Chemical Composition | Temper | Mechanical Properties | ||||

| Tensile strength | Elongation | Grain Size | |||||

| CU% | P% | ||||||

| C12200 | 99.9 | 0.015-0.040 | H58 | 250 Mpa | – | – | |

| O60 | 205 Mpa | ≥40% | – | ||||