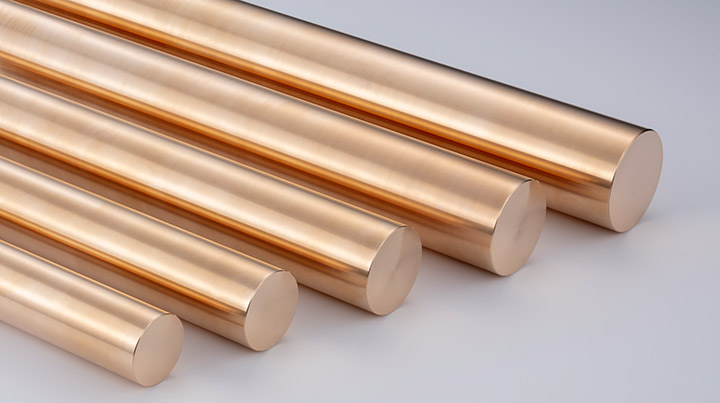

Product Introduction

Pure copper is a rose-red metal, and it turns purple after a copper oxide film is formed on the surface, so industrial pure copper is often called red copper or electrolytic copper. The density is 8-9g/cm3 and the melting point is 1083°C. Pure copper has good electrical conductivity and is widely used in the manufacture of wires, cables, brushes, etc.; it has good thermal conductivity and is often used to manufacture magnetic instruments and meters that must be protected from magnetic interference, such as compasses, aviation instruments, etc.; excellent plasticity, easy to heat Pressed and cold pressed, it can be made into copper materials such as pipes, rods, wires, strips, strips, plates, foils, etc.

Chemical Typical

C10100 99.99 Min 0.0005 Max 0.0005 Max C10200 99.95 Min 0.0001 Max 0.0003 Max

C10400 99.95 minutes 0.0001 0.027 minutes maximum

C10500 99.95 minutes 0.0001 0.034 minutes maximum

C10700 99.95 minutes 0.0001 0.085 minutes maximum

C11000 99.90 minutes

C12000 99.90 minutes 0.004-0.012

C12100 99.90 minutes 0.014 0.004-0.012

C15000 Balance* 0.10-0.20 Zr C15500 99.75 min 0.027-0.10 0.400-0.080 0.08-0.13 Mg

Description

| Product name | Copper bar |

| Standard | ASTM,AISI,EN,BS,JIS,ISO,GB |

| Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930,

C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200, C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800, C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200, T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1,etc |

| Specifications | Diameter:3~200mm |

| Length:2m,3m,5.8m,6m,or as required. | |

| Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required. |

| Price term | Ex-work, FOB, CFR, CIF, etc. |

| Payment term | T/T, L/C, Western Union, etc. |

| Delivery time | According to order’s quantity. |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport,or be required. |

National Copper Grades

| CN | GER | EUR | INT | USA | JPN | ||

| GB | DIN | EN | ISO | UNS | JIS | ||

| TU2 | OF-Cu | 2.0040 | Cu-OFE | CW009A | Cu-OF | C10100 | CJ0ll |

| – | SE-Cu | 2.0070 | Cu-HCP | CW021A | • | Cl0300 | • |

| – | SE-Cu | 2.0070 | Cu-PHC | CW020A | – | Cl0300 | – |

| T2 | E-Cu58 | 2.0065 | Cu-ETP | CW004A | Cu-ETP | C11000 | CH00 |

| TP2 | SF-Cu | 2.0090 | Cu-DHP | CW024A | Cu-DHP | Cl 2200 | Cl 220 |

| • | SF-Cu | 2.0090 | Cu-DHP | CW024A | Cu-DHP | Cl2200 | Cl 220 |

| – | SF-Cu | 2.0090 | Cu-DHP | CW024A | Cu-DLP | Cl 2200 | Cl 220 |

| TP1 | SW-Cu | 2.0076 | Cu-DLP | CW023A | Cu-DLP | Cl 2000 | C1201 |

| H96 | CuZn5 | 2.0220 | CuZn5 | CE500L | CuZn5 | C21000 | C2100 |

| H90 | CuZn10 | 2.0230 | CuZnlO | CW501L | CuZnl0 | C22000 | C2200 |

| H85 | CuZn15 | 2.0240 | CuZnl5 | CW502L | CuZn15 | C23000 | C2300 |

| H80 | CuZn20 | 2.0250 | CuZn20 | CW503L | CuZn20 | C24000 | C2400 |

| H70 | CuZn30 | 2.0265 | CuZn30 | CW505L | CuZn30 | C26000 | C2600 |

| H68 | CuZn33 | 2.0280 | CuZn33 | CW506L | CuZn35 | C26800 | C2680 |

| H65 | CuZn36 | 2.0335 | CuZn36 | CW507L | CuZn35 | C27000 | C2700 |

| H63 | CuZn37 | 2.0321 | CuZn37 | CW508L | CuZn37 | C27200 | C2720 |

| HPb63-3 | CuZn36Pb1.5 | 2.0331 | CuZn35Pb1 | CW600N | CuZn35Pb1 | C34000 | C3501 |

| HPb63-3 | CuZn36Pb1.5 | 2.0331 | CuZn35Pb2 | CW60IN | CuZn34Pb2 | C34200 | – |

| H62 | CuZn40 | 2.0360 | CuZn40 | CW509N | CuZn40 | C28000 | C3712 |

| H60 | CuZn38Pb1.5 | 2.0371 | CuZn38Pb2 | CW608N | CuZn37Pb2 | C35000 | – |

| HPb63-3 | CuZn36Pb3 | 2.0375 | CuZn36Pb3 | CW603N | CuZn36Pb3 | C36000 | C3601 |

| HPb59-l | CuZn39Pb2 | 2.0380 | CuZn39Pb2 | CW6I2N | CuZn38Pb2 | C37700 | C3771 |

| HPb58-2.5 | CuZn39Pb3 | 2.0401 | CuZn39Pb3 | CW614N | CuZn39Pb3 | C38500 | C3603 |

| – | CuZn40Pb2 | 2.0402 | CuZn40Pb2 | CW6I7N | CuZn40Pb2 | C38000 | C3771 |

| • | CuZn28Sn1 | 2.0470 | CuZn28Sn1As | CW706R | CuZn28Sn1 | C68800 | C4430 |

| – | CuZn31Si1 | 2.0490 | CuZn31Si1 | CW708R | CuZn31Si1 | C44300 | – |

| – | CuZn20A12 | 2.0460 | CuZn20A12As | CW702R | CuZn20A12 | C68700 | C6870 |

| QSn4-0.3 | CuSn4 | 2.1016 | CuSn4 | CW450K | CuSn4 | C51100 | C5111 |

| – | CuSn5 | 2.1018 | CuSn5 | CW451K | CuSn5 | C51000 | C5102 |

| QSn6.5-0.l | CuSn6 | 2.1020 | CuSn6 | CW452K | CuSn6 | C51900 | C5191 |

| QSn8-0.3 | CuSn8 | 2.1030 | CuSn8 | CW453K | CuSn8 | C52100 | C5210 |

| BZn12-24 | CuNi12Zn24 | 2.0730 | CuNil2Zn24 | CW403J | CuNil2Zn24 | C75700 | . |

| BZn 12-26 | CuNi18Zn27 | 2.0742 | CuNi18Zn27 | CW410J | CuNil8Zn27 | C77000 | C7701 |

| BZnl8-18 | CuNi18Zn20 | 2.0740 | CuNi18Zn20 | CW409J | CuNil8Zn20 | C76400 | C7521 |

| – | CuNi10Fe1Mn | 2.0872 | CuNi10Fe1Mn | CW352H | CuNilOFeIMn | C70600 | C7060 |

| • | CuNi30Mn1Fe | 2.8820 | CuNi30Mn1Fc | CW354H | CuNBOMnlFe | C71500 | C7150 |

Copper

| BS | BS EN | Description |

| C101 | CW004A | Electrolytic Tough Pitch (ETP) is a commonly used grade of copper for electrical applications. |

| C103 | CW008A | Oxygen Free Copper is an oxygen free copper with a minimum copper content of 99.95%. |

| C106 | CW024A | Phosphorus De-oxidised Copper has the oxygen removed through the controlled addition of phosphorous, making it more easily weldable. |

| C109 | CW118C | Tellurium Copper (free cutting) has 0.5% tellurium which raises the machinability but has a limited effect on both ductility and conductivity. |

| C110 | CW009A | Oxygen Free (High Conductivity) Copper contains 99.99% copper with limited impurities when compared to other grades. This grade is the purest of the oxygen free coppers. |

| C111 | CW114C | Sulphur Copper (Free Machining) has a machinability rating of approximately 80% which is due (in part) to the addition of sulphur. |

| C101AG2 | CW011A | Silver-Bearing Copper features the addition of copper to improve the resistance to softening. These grades also feature improved electrical conductivity and resistance to heat and corrosion. |

| C101AG3 | CW012A | |

| C101AG4 | CW013A | |

| CC102 | CW106C | Copper Chrome Zirconium contains small amounts of zirconium as well as chromium which help to improve mechanical performance. |